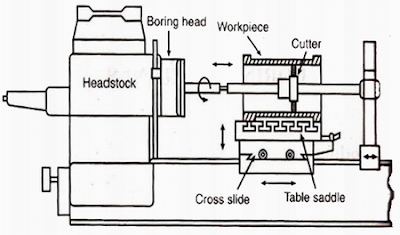

In a horizontal boring machine, the work is supported on a table which is stationary and the tool revolves in a horizontal axis.

A horizontal boring machine can perform boring, reaming, turning, threading, facing, milling, grooving and many other operations with suitable tools.

Different types of horizontal boring machines have been designed to suit different purposes.

Parts of Horizontal boring machine :

Bed :

The bed is fitted on the floor of the shop and has a box-like casting.

The bed supports the columns, tables and other parts of the machine.

Headstock supporting column :

The column provides supports to the headstock and guides it up and down accurately by the guideways provided on the face of the column.

End supporting column :

The end supporting column situated at the other end of the bed houses the bearing block for supporting a long boring bar.

Headstock :

The headstock mounted on the column supports, drives, and feed the tool.

The headstock may be moved up and down on the column for setting the tool for different heights of the work.

Saddle and table :

The table supports the work and provided with T-slots for clamping the work or for holding devices.

The saddle allows the work to be moved longitudinally on the bed.

The table may be moved crosswise on the saddle.

Boring bars :

The boring bar supports the cutter for boring operations on jobs having large bore diameters.

Size of horizontal boring machine :

The size of that is specified by the diameter of its spindle in mm.

Spindle diameter varies from 75 to 355 mm.

Other important dimensions such as spindle motor horsepower, column heights, size of the table or size of the floor plate, spindle speed, feed and length of feeds, floor space required, the weight of the machine should be stated.

Boring machine mechanism :

The boring machine has different controls for movements of the different parts of the machine. A table type machine has movements mentioned below :

As all the controls are housed in a particular position of the machine the operator may give closed attention on the work while controlling the machine.

Work holding device for horizontal boring machine :

There are different boring tool used in boring bars are of different shapes and sizes for different types of operation.

A horizontal boring machine can perform boring, reaming, turning, threading, facing, milling, grooving and many other operations with suitable tools.

Different types of horizontal boring machines have been designed to suit different purposes.

Parts of Horizontal boring machine :

Bed :

The bed is fitted on the floor of the shop and has a box-like casting.

The bed supports the columns, tables and other parts of the machine.

Headstock supporting column :

The column provides supports to the headstock and guides it up and down accurately by the guideways provided on the face of the column.

End supporting column :

The end supporting column situated at the other end of the bed houses the bearing block for supporting a long boring bar.

Headstock :

The headstock mounted on the column supports, drives, and feed the tool.

The headstock may be moved up and down on the column for setting the tool for different heights of the work.

Saddle and table :

The table supports the work and provided with T-slots for clamping the work or for holding devices.

The saddle allows the work to be moved longitudinally on the bed.

The table may be moved crosswise on the saddle.

Boring bars :

The boring bar supports the cutter for boring operations on jobs having large bore diameters.

Size of horizontal boring machine :

The size of that is specified by the diameter of its spindle in mm.

Spindle diameter varies from 75 to 355 mm.

Other important dimensions such as spindle motor horsepower, column heights, size of the table or size of the floor plate, spindle speed, feed and length of feeds, floor space required, the weight of the machine should be stated.

Boring machine mechanism :

The boring machine has different controls for movements of the different parts of the machine. A table type machine has movements mentioned below :

- The headstock and the end supporting block may be moved up and down.

- The spindle may be rotated with different speeds.

- The spindle may be moved in or out by hand or power for feeding.

- The saddle or table may be moved by hand pr power.

- The columns may be moved by hand or power.

As all the controls are housed in a particular position of the machine the operator may give closed attention on the work while controlling the machine.

Work holding device for horizontal boring machine :

- Conventional work holding devices comprise of T-bolts and clamps, angle plates, step blocks etc.

- Special jigs are used in mass production work.

Horizontal boring machine operations :

In boring machine used for milling operation and the milling cutter may be fitted to the spindle.

Facing cutter is used for machining flat vertical surfaces for face milling operation.

End mills are used to produce grooves and slots.

Other operations such as following below :

- Drilling

- Reaming

- Counter boring

- Tapping

- Spot facing

Boring tool mountings for horizontal boring machine :

The different equipment for mounting cutters in horizontal boring machine are :

- Boring bar

- Boring head or cutter head

- Facing head

There are different boring tool used in boring bars are of different shapes and sizes for different types of operation.