Die casting is a permanent mould manufacturing process. It was first developed in the early 1900s. Die casting is a widely spread technique for which the metal is forced into the mould cavity under high pressure and produced geometrical complex metal parts through the use of reusable moulds is called dies. In this process involves furnace, metal, die casting machine and die. The mould cavity is like intricate in designs that enable in producing complex shapes with good surface finish, high accuracy and attractiveness.

Working principle of die casting :

Die casting process complete in five stages that we can discuss below :

- Clamping

- Injection

- Cooling

- Ejection

- Trimming

The die casting machine is two types :

- Hot chamber die casting

- Cold chamber die casting

In between two types, the main difference is that in the hot chamber machine, the holding furnace for the liquid metal is integral with the die casting machine. wherein cold chamber machine, the metal is melted in a separate furnace after that metal is poured into the die casting machine with a ladle for each casting cycle is called shot.

Hot chamber dies casting machine :

Hot chamber process is also called gooseneck casting. Hot chamber machines are used for alloys with low melting temperatures, such as zinc, tin, and lead. The gooseneck is made of grey alloy or ductile iron or of cast steel. The operating sequence of this process is typical injection pressures for a hot chamber die casting machine are between 1000 and 5000 psi. After the molten metal has been injected into the die cavity and then the plunger remains down, holding the pressure while the casting solidifies. After solidification, the hydraulic system retracts the plunger and the part can be ejected by the clamping unit. the plunger moves back returning the used liquid metal to the gooseneck. The casting which is in the ejector die is now ejected then the plunger uncovers the filling hole, letting the liquid metal from the furnace to enter the gooseneck.

In the hot chamber die casting process the direct immersion in the molten metal allows for quick and convenient mould injection, it also results in increased corrosion susceptibility. Because of these characteristics, the hot-chamber die casting process is best suited for applications that utilize metals with low melting points and high fluidity. Good metals for the hot-chamber die casting process include lead, magnesium, zinc and copper.

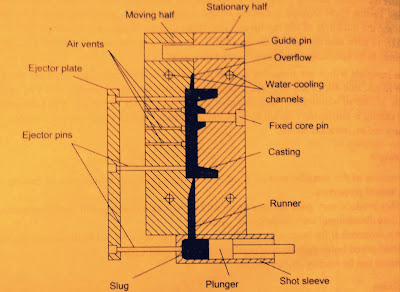

Cold chamber dies casting machine :

The hot chamber process is used for most of the low melting temperature alloys while materials such as aluminium and brass. High melting temperature makes it difficult to cast them with the use of a hot chamber process because gooseneck of the hot chamber machine is continuously in contact with the molten metal.

In the cold chamber process, the molten metal is poured with a ladle into the shot chamber. this process reduces the contact time between the liquid metal and the shot chamber.

The operation is similar to that of the hot chamber process start with the spraying die lubricants throughout the die cavity and closing the die when molten metal is ladled into the shot chamber of the machine either manually or by hand or by means of the auto ladle. Then plunger forces the metal into the die cavity and maintains the plunger the pressure till it solidifies then die opens. The casting is ejected. At the same time plunger returns to its original position and completing the operation.

For hot chamber die casting characteristics is too corrosive for the immersion design while the cold-chamber process can be an excellent alternative.

Die design :

Hot-working tool steels are normally used for the preparation of the dies, die inserts and cores. The die must allow the molten metal to flow easily into all of the cavities. Equally important is the removal of the solidified casting from the die, that is why the draft angle must be applied to the walls of the part cavity. The design of the die must also accommodate any complex features on the part such as undercuts will require additional die pieces.

- For zinc alloy, the normal die material is AISI P20 for low volume and H13 for high volume.

- For aluminium and magnesium H13 and H11 are used.

- For copper alloy H20, H21 and H22 are used as die material.

High-grade tool steel is the most common and is typically used for 100-150,000 cycles. Steels with low carbon content are more resistant to cracking and can be used for 1,000,000 cycles.

Benefits of the die casting process :

- High quality :

- High reliability :

- Quick production :

- Minimal assembly :

- Versatile design :

Die casting application :

- It is suitable for casting medium-sized parts with complex details.

- It is widely used in manufacturing commercial, industrial products, automobile industries and aerospace.

- The typical products like carburettors, crank-cases, magnetos, handlebar housing, other parts of scooters, motorcycles and mopeds, zip fasteners and gears.

Properties and characteristics of the die casting process :

- Parts manufactured by this process are close tolerance, very high surface finish and thin intricate walls.

- Production rate is very high.

- Equipment cost for die casting is generally high but its assembly is easy.

- This process is highly automated so the labour cost is low.

- Parts that manufactured by this process are with superior mechanical properties because of rapid cooling.

- Ejector pins will usually leave small round marks on the metal casting so this will be observed on the surface of manufactured parts.

Because of these properties and characteristics, this process has many advantages and it is widely used in manufacturing industries