Introduction :

Atomic hydrogen welding is an arc welding process. In this process the arc used in between two tungsten electrodes in a shielding atmosphere of hydrogen. This process was invented by Irving Langmuir in the course of his studies of atomic hydrogen. When Hydrogen is in its atomic state, is a strong reducing gas which prevents oxidation of weld metal and rapid burning of electrodes. Any oxygen present in the surrounding combines with hydrogen forming water which is converted into steam.

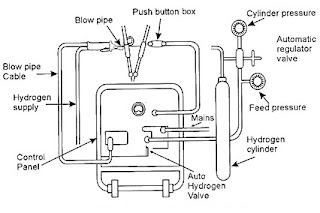

Equipment set up :

Set up of this operation consist of hydrogen cylinder, an AC welding machine and the welding torch to accommodate to tungsten electrons, with provision for changing the distance between them. The normal voltage range of the power supply is between 50 to 75 volt with the current varying from 15 to 150 A. This measure is good enough for an electrode size of 1 to 5 mm.

The path of electron travel between the two electrodes is not a straight path as in other arc welding process. Instead, they travel in the form of a fan. This is because the hydrogen atoms formed by the arc causes a downward force because of with electron flow slightly deviates. This fan shape can be changed by altering the distance between the electrodes and the current level. The DC machines could also be used in atomic hydrogen welding, but because of the electron flow is only in one direction, the wear of electron is particularly high and as a result, only AC power supply is used.

When hydrogen atoms recombine near the workpiece surface, they generate a temperature of the order of the 300 0C. Because of this heat, the molten metal becomes highly fluid and therefore, atomic hydrogen welding is used for the flat position only. Filler metal when needed is melted intermittently in the arc fan for fusing with the base metal.

Application :

When properly performed, atomic hydrogen welding gives an extremely clean weld with excellent quality. It is generally used for welding of tool Steels containing tungsten, Nickel and Molybdenum as also for hard surfacing and repairing of moulds, dies and tools. Though it can be used for any job, its high cost prohibits its general usage.

Atomic hydrogen welding is an arc welding process. In this process the arc used in between two tungsten electrodes in a shielding atmosphere of hydrogen. This process was invented by Irving Langmuir in the course of his studies of atomic hydrogen. When Hydrogen is in its atomic state, is a strong reducing gas which prevents oxidation of weld metal and rapid burning of electrodes. Any oxygen present in the surrounding combines with hydrogen forming water which is converted into steam.

Equipment set up :

Set up of this operation consist of hydrogen cylinder, an AC welding machine and the welding torch to accommodate to tungsten electrons, with provision for changing the distance between them. The normal voltage range of the power supply is between 50 to 75 volt with the current varying from 15 to 150 A. This measure is good enough for an electrode size of 1 to 5 mm.

The path of electron travel between the two electrodes is not a straight path as in other arc welding process. Instead, they travel in the form of a fan. This is because the hydrogen atoms formed by the arc causes a downward force because of with electron flow slightly deviates. This fan shape can be changed by altering the distance between the electrodes and the current level. The DC machines could also be used in atomic hydrogen welding, but because of the electron flow is only in one direction, the wear of electron is particularly high and as a result, only AC power supply is used.

When hydrogen atoms recombine near the workpiece surface, they generate a temperature of the order of the 300 0C. Because of this heat, the molten metal becomes highly fluid and therefore, atomic hydrogen welding is used for the flat position only. Filler metal when needed is melted intermittently in the arc fan for fusing with the base metal.

Working

principle :

Atomic hydrogen welding the atomic hydrogen welding is an

inert gas welding arc welding process done with non-consumable electrodes. The

main difference between tungsten inert gas welding and this process is that in atomic hydrogen

welding, the arc is obtained between the two tungsten electrodes rather than

between the tungsten electrode and the workpiece. This shielding gas used here

is hydrogen, which is reactive in nature compared to argon. The hydrogen

molecule (H2), when passing through the electric arc, get this dissociated

into two hydrogen atoms (H+). The hydrogen atoms are highly reactive. They

form hydrogen molecule and combine with oxygen if present to form water vapour

enters release intense heat for the necessary melting of the joint. Because of

its type reactivity, the atomic hydrogen is able to break the oxide on the base

metal and thus allow the formation of a clean weld.

When properly performed, atomic hydrogen welding gives an extremely clean weld with excellent quality. It is generally used for welding of tool Steels containing tungsten, Nickel and Molybdenum as also for hard surfacing and repairing of moulds, dies and tools. Though it can be used for any job, its high cost prohibits its general usage.