The slotting machine was developed

by Brunel in the year 1800 much earlier than

a shaper was invented. It falls under the category of the reciprocating

type of machine tool similar to a shaper or a planer. Both are operated almost

on the same principle but the major difference between them is in a slotter the

ram holding the tool reciprocates in a vertical axis, whereas in a shaper the

ram holding the tool reciprocates in horizontal axes.

What is slotting machine?

Slotting machine is vertically reciprocating machine tool used for making a mortise or shaping the sides of an aperture, in which ram holding the tool reciprocates in a vertical axis and the cutting action of the tool is only during the return downward stoke.

The slotting machine is used for cutting grooves, keyways and slots of :

- Various shapes

- For making regular and irregular surfaces both internal

and external.

It is also used for handling large

and awkward workpieces, for cutting internal and external gears and many other

operations which can't be conventionally machined in any other machine tools.

Types of slotter machine :

There are mainly two types of slotter machine :

- Puncher slotter

- Precision slotter

Puncher slotter :

It is heavy, a rigid machine designed

for removal of a large amount of metal from large forging or casting.

The length of puncher slotter is large it may be as long as 1800 to 2000 mm.

In this machine puncher slotter, ram is usually driven by a spiral pinion meshing with the rack teeth cut on the underside of ram. The pinion is driven by a variable speed reversible electric motor similar to that of a planer.

In this machine, feed is also controlled by electrical gear.

Precision slotter :

It is a lighter machine and is operated at high speeds.

This machine is designed to take

light cuts giving an accurate finish.

By using special jigs, the machine can handle a number of identical works on a production basis.

This machine is also used for general-purpose work and is usually fitted with a whitworth quick return mechanism.

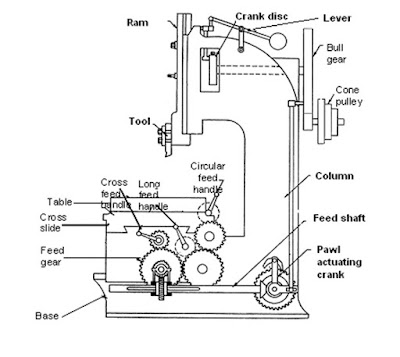

Parts of slotter machine :

- Base

- Column

- Saddle

- Cross-slide

- Rotating table

- Ram and tool head assembly

- Ram drive mechanism

- Feed mechanism

Now we can see parts in details :

Base or bed :

The base is rigidly and it takes up all the cutting forces and entire load of the machine.

It is the key parts of the machine that made from cast iron.

The top of the bed is accurately finished to provide guideways on which the saddle is mounted. The guideways are perpendicular to the column face.

Column :

The column is the

vertical member which is made up of cast iron.

The column is assembled with the base and houses driving mechanism of the ram and feeding mechanism.

The vertical front face of the column is accurately finished for providing ways in which the ram reciprocates up and down.

Saddle :

The saddle is mounted upon the guideways and may be moved towards or away from the column either by power or manual control to supply longitudinal feed to the work.

The top face of the saddle is accurately finished to provide guidance for the cross-slide. These guideways are perpendicular to the guideways on the base.

Cross-slide :

The cross slide is mounted upon the guideways of the saddle and may be moved parallel to the base of the column.

The movement of the slide may be controlled either by hand or power to supply crossfeed.

The circular worktable is mounted on the top of the cross-slide.

Handwheels :

It is provided for rotating the table for the longitudinal and cross traverse.

Rotary table :

The rotary table is a circular table which is mounted on the top of the cross slide.

The table may be rotated by rotating a worm which meshes with a worm gear connected to the underside of the table.

The rotation of the table may be affected either by hand or power.

The rotary table enables a circular or contoured surface to be generated on the work piece.

Ram and tool head assembly :

The run is reciprocating member of the machine mounted on the guideways of the column.

It supports the tools at its bottom end on a tool head.

A Slot is cut on

the body of the ram for changing the position of the stock.

In some mechanism, a special type of tool holders is provided to relieve the tool during the return stroke.

Ram drive mechanism :

A slotter removes metal during the downward cutting stroke. No metal removed during the upward return stroke.

The usual types of

ram drive mechanisms are :

- Whitworth quick return mechanism

- Variable speed reversible motor drive mechanism

- Hydraulic drive mechanism

The operation performed on slotter

machine :

- Machining internal and external flat surfaces.

- Internal recess of circular, semi-circular, concave and

convex surfaces.

- Machining internal and external circular surfaces.

- Internal machining of blind holes.

- For shaping internal and external forms or profiles.

- Machining vertical, angular or inclined surfaces.

- Machining irregular surface which is difficult to

produce.

- For machining dies and punches.

- To cut slots, grooves, splines and keyways for both

internal and external surfaces.

- Machining internal and external gear teeth.

Cutting speed :

The rate at which the metal is removed during downward cutting stroke is called cutting speed.

It is expressed in meters /

minute.

Depth of cut :

The perpendicular distance measured between the machined surface and the un-machined surface called the depth of cut.

It is expressed in mm.

Feed :

The movement of the work per double stroke is called feed.

It is expressed in mm.