Bearing is a mechanical element that permits relative motion between two parts, such as the shaft and the housing, with minimum friction.

The function of the bearing are the following :

Depending upon the direction of the force that acts on them :

Thrust bearing supports the load, which acts along the axis of the shaft.

Depending upon the types of friction :

Application of Rolling contact bearing :

The function of the bearing are the following :

- The bearing ensures free rotation of the shaft or axle with minimum friction.

- The bearing supports the shaft or axle and holds it in the correct position.

- The bearing takes up the forces that act on the shaft or the axle and transmit them to the flame.

Depending upon the direction of the force that acts on them :

- Radial bearing

- Thrust bearing

Thrust bearing supports the load, which acts along the axis of the shaft.

Depending upon the types of friction :

- Sliding contact bearing

Types of sliding contact bearing :

- Hydrodynamic bearing

- Hydrostatic bearing

- Rolling contact bearing

- Deep groove ball bearing

- Cylindrical roller bearing

- Angular contact bearing

- Self-aligning bearing

- Taper roller bearing

- Thrust ball bearing

Sliding contact bearing is also called plain bearing, journal bearing or sleeve bearing.

Lubrication is critical to the operation of plain bearings, so their application and function are also often referred to according to the type of lubrication principle used. Thus, terms such as hydrodynamic, fluid-film, hydrostatic, boundary-lubricated, and self-lubricated are designations for particular types of plain bearings.

Application of Sliding Contact Bearing :

Lubrication is critical to the operation of plain bearings, so their application and function are also often referred to according to the type of lubrication principle used. Thus, terms such as hydrodynamic, fluid-film, hydrostatic, boundary-lubricated, and self-lubricated are designations for particular types of plain bearings.

Application of Sliding Contact Bearing :

- Crankshaft bearing in petrol and diesel engine

- Centrifugal pumps

- Large size electric motor

- Steam and gas turbine

- Rope conveyors

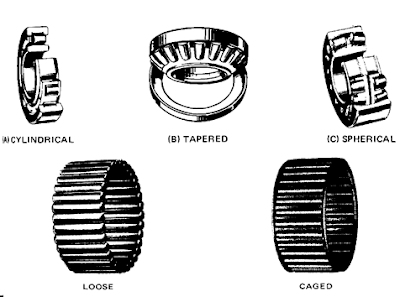

The principal types of roller bearings are cylindrical, needle, tapered, and spherical. In

general, they have higher load capacities than ball bearings of the

same size and are widely used in heavy-duty, moderate-speed

applications. However, except for cylindrical bearings, they have lower

speed capabilities than ball bearings. See the following figure for

roller bearings.

Application of Rolling contact bearing :

- Machine tool spindles

- Automobile front and real axles

- Gear boxes

- Small size electric motors

- Rope sheaves

- Crane hooks

- Hoisting drums