Construction and working of simple

carburettor:

Carburettors are highly complex provides an air-fuel mixture for

cruising or normal range at a single speed. Later, other mechanisms to provide

for the various special requirements like starting, idling, variable load and

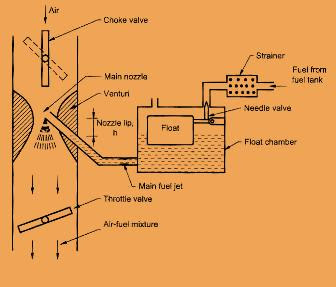

speed operation and acceleration will be included. Below Figure shows that the

details of the simple carburettor.

The simple

carburettor mainly consists of a float chamber, fuel discharge nozzle and a

metering orifice, a venturi, a throttle valve and a choke. The float and a

needle valve system maintains a constant level of gasoline in the float

chamber.

If the amount of

fuel in the float chamber falls below the designed level, the float goes down,

thereby opening the fuel supply wire and admitting fuel. The float closes the

fuel supply valve thus stopping additional fuel flow from the supply system

when the design level has been reached. The float chamber is vented either to the

atmosphere or to the upstream side of the venturi.

During suction

stroke air is drawn through the venturi. Now the first question arise in your mind

that what is venturi?

It is a tube of

decreasing cross-section with a minimum area at the throat. Venturi tube is

also known as the chock tube and is shaped that it offers minimum resistance to

the airflow. The velocity increases and reaching a maximum at the venturi

throat when the air is passing through the venturi.

Correspondingly,

the pressure decreases and reaches a minimum. From the float chamber, the fuel

is fed to a discharge jet, the tip of which is located in the throat of

venturi. Fuel is discharged into the airstream because of differential

pressure known as carburettor depression. The fuel discharge is affected by

the size of the discharge jet and it is used to give the required air-fuel ratio.

As the throttle is fully opened the pressure lies between 4 to 5 cm of HG,

below atmospheric and sometimes exceeds 8 cm Hg below atmospheric.

To avoid overflow

of fuel through the jet, the level of liquid in the float chamber is maintained

at a level slightly below the tip of the discharge jet. It is also known as the tip

of the nozzle. The difference in the height between the top of the nozzle and

the float chamber level is marked as h.

The gasoline engine

is quantity governed, which means that when the power output is to be varied at a

particular speed, the amount of charge delivered to the cylinder is varied.

This is achieved by means of a throttle valve. All the parts and its functions are described below.

A carburettor consists of the

following main parts :

- Fuel strainer

- Float chamber

- Main fuel metering and idling nozzles

- Chock and throttle

Parts that mentioned above are

discussed briefly below :

- The fuel strainer :

As petrol has to pass through a

narrow nozzle exit there is every possibility that the nozzle may get clogged

prolonged operation of the engine. To prevent this possibility of blockage of

the nozzle by dust particles, the petrol is filtered by installing a fuel the strainer at the inlet of the float chamber.

The strainer made of a fine wire

mesh or other types of filtering device. The fuel strainer is either cone-shaped

or cylindrical shape.

- The float chamber :

The float chamber is to supply the

fuel to the nozzle at a constant pressure head. This is possible by maintaining

a constant level of fuel in the float bowl. The float in a carburettor is provided to control the level of fuel in the float chamber. In order to provide

the correct amount of fuel and to prevent the leakage of fuel from the nozzle

fuel level must be maintained slightly below the discharge nozzle outlet

holes.

- The main fuel metering and idling system :

The main fuel metering system of the

carburettor controls the fuel feed for cruising and the full-throttle

operations.

It consists of three principles:

- The fuel metering orifice through which fuel is drawn

from the float chamber.

- The main discharge nozzle.

- The passage leading to the idling system.

The main three functions of the main metering system is:

- To proportion the air-fuel mixture.

- To decrease the pressure at the discharge nozzle exit.

- To limit the airflow at full throttle.

- Chock and throttle :

When the vehicle is kept stationary for

a long period during cold weather, it may be overnight too then starting of

vehicle becomes more difficult.

For a low intake temperatures and

cranking speed a very rich mixture is required to initiate the combustion. The

main reason is that a very large fraction of fuel may remain as liquid suspended

in the air even in the cylinder. The most popular method of providing such mixture

is by the use of chock valve.

Throttle valve controlled the speed

and the output of an engine. The more the throttle is closed the greater is the

obstruction to the flow of the mixture placed in the passage and the less is

the quantity of mixture delivered to the cylinders.

As the throttle is opened, the

output of the engine increases. But this is not always the case as the load on

the engine is also a factor.

As we discuss the throttle is simply

a means to regulate the output of the engine by varying the quantity of charge

going into the cylinder.

Drawback of simple

carburettor:

- A fundamental drawback is providing the required A/F

ratio only at one throttle position.

- While at the other throttle positions the mixture is either leaner or richer depending on whether the throttle is opened less or more.