The Solex carburettor is famous for its ease of starting, good performance and reliability. It is one type of down draught carburettor. This carburettor is made in various models and is also used n many automobile engines. This carburettor has also various fuel circuits same as in simple carburettor.

In Solex carburettor the incorporates device called bi-starter which is unique for this carburettor. This device is very useful for cold starting of the engine.

We can check to work of this carburettor in different conditions :

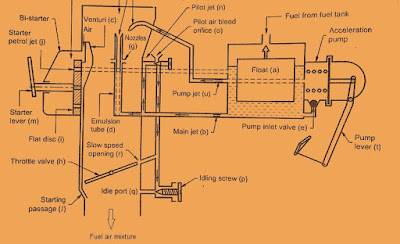

All description shows from the above figure.

In Solex carburettor the incorporates device called bi-starter which is unique for this carburettor. This device is very useful for cold starting of the engine.

We can check to work of this carburettor in different conditions :

All description shows from the above figure.

- Normal running :

In normal running, afloat with a tapered needle valve at the top face of the float is fixed in the float chamber. This tapered valve takes care of the level of fluid in float-chamber. The main metering jet supplies fuel and the air comes through the venturi. The fuel from the main jet goes into the well of the air-bleed emulsion system. Air correction jet calibrates the air entering through it and ensures automatically the correct-balance of the air and fuel. The metered emulsion of fuel and air is supplied through the spraying orifice or nozzles. These nozzles are drilled horizontally in the vertical standpipe in the middle of the chock tube or the venturi.

- Cold starting and warming :

In a cold starting condition starter valve is in the form of a flat disc with hoes of different sizes. These holes connect the starter gasoline jet and starter air jet sides to the passage which opens into a hole just below the throttle valve. Smaller or bigger size holes come opposite the passage depending upon the position of the starter lever. The starter level is operated by flexible cable from the dashboard control. After that inducting gasoline from jet and air from jet are shaped that the mixture provided to the carburettor is rich enough for starting.

- Idling and slow running :

- Acceleration :

Pump supplied extra fuel needed for acceleration through pump injector. Pump lever is connected to the accelerator. When the pedal is pressed by foot the lever moves towards left and presses the pump diaphragm towards left. This force the gasoline through pump jet and injector. On releasing the pressure on the pedal, the lever moves the diaphragm back towards the right so it creates vacuum towards left. The vacuum so created opens the pump inlet valve and gasoline from the float chamber enters the pump.