Introduction :

In plasma arc welding plasma is the state of the matter when part of the gas is ionized making it a conductor of electric current. It is the state of matter present in between the electrode in an arc. The plasma arc welding closely resembles that of the TIG welding in that it also uses a non-consumable tungsten electrode and a shielding gas such as argon.

The plasma welding process was introduced to the welding industry as a method of bringing better control to the arc welding process in lower current ranges.

How does it work?

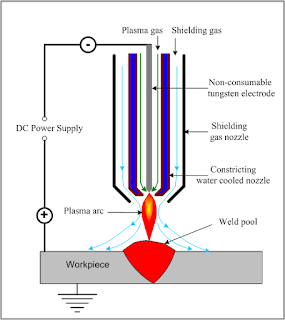

In plasma arc welding, the plasma arc is tightly constrained and a small amount of pure argon gas flow is allowed through the inner orifice surrounding the tungsten electrode to form the plasma gas.

To initiate the arc in PAW, a low current pilot arc is obtained between the electrode and the constricting nozzle which is heated to an extremely high temperature and ionized so that it becomes electrically conductive. The arc in this type of welding is concentrated and straight. and similar to tungsten inert gas welding plasma to transfer an electric arc to a workpiece. The metal to be welded is melted by the intense heat of the arc and metal fuses together thus welding is done.

In plasma welding torch a tungsten electrode is located within a copper nozzle having a small opening at the tip. A pilot arc is produced between the torch electrode and nozzle tip. This arc is then transferred to the metal to be welded.

The plasma gas itself is not sufficient to protect the weld metal therefore, a large volume of inert-shielding gas is allowed to flow through an outer gas nozzle surrounding the inner nozzle. Plasma gases are normally argon. The torch also uses a secondary gas surcharge, argon/hydrogen or helium which assists in shielding the molten weld puddle thus minimizing the oxidation of the weld.

The power source used is DC with electrode negative for better electrode life.

The actual welding by PAW is done by means of a technique called a keyhole.

In plasma arc welding plasma is the state of the matter when part of the gas is ionized making it a conductor of electric current. It is the state of matter present in between the electrode in an arc. The plasma arc welding closely resembles that of the TIG welding in that it also uses a non-consumable tungsten electrode and a shielding gas such as argon.

The plasma welding process was introduced to the welding industry as a method of bringing better control to the arc welding process in lower current ranges.

How does it work?

In plasma arc welding, the plasma arc is tightly constrained and a small amount of pure argon gas flow is allowed through the inner orifice surrounding the tungsten electrode to form the plasma gas.

To initiate the arc in PAW, a low current pilot arc is obtained between the electrode and the constricting nozzle which is heated to an extremely high temperature and ionized so that it becomes electrically conductive. The arc in this type of welding is concentrated and straight. and similar to tungsten inert gas welding plasma to transfer an electric arc to a workpiece. The metal to be welded is melted by the intense heat of the arc and metal fuses together thus welding is done.

In plasma welding torch a tungsten electrode is located within a copper nozzle having a small opening at the tip. A pilot arc is produced between the torch electrode and nozzle tip. This arc is then transferred to the metal to be welded.

The plasma gas itself is not sufficient to protect the weld metal therefore, a large volume of inert-shielding gas is allowed to flow through an outer gas nozzle surrounding the inner nozzle. Plasma gases are normally argon. The torch also uses a secondary gas surcharge, argon/hydrogen or helium which assists in shielding the molten weld puddle thus minimizing the oxidation of the weld.

The power source used is DC with electrode negative for better electrode life.

The actual welding by PAW is done by means of a technique called a keyhole.

Equipment Required List :

- Power Supply

- Plasma Console (sometimes external, sometimes built-in)

- Water re-circulator (sometimes external, sometimes built-in)

- Plasma Welding Torch

- Torch Accessory Kit (Tips, ceramics, collets, electrodes set-up gages)

Advantages of plasma arc welding :

- The main advantages of this are lies in the control and quality produced in the part being welded.

- The torch design allows for better control of the arc, as well as a higher tolerance for in torch standoff distance.

- Welds are typically cleaner and smoother in PAW process.

- Smaller heat affected zone results welds are very strong.

- Metal deposit rates are high.

Limitations of plasma arc welding :

- Welding equipment is expensive.

- Nozzle surrounding the electrode needs a frequent replacement.

- Relatively high startup costs.

- High skilled workers required.