Introduction :

Shielded metal arc welding is also called as manual metal arc welding. It is the most extensively used manual welding process, which is done with stick electrodes. Though in the USA, its use is decreasing in comparison to the other arc welding process. In India, it still is the most used arc welding process. This process is highly versatile and can be used extensively for both simple as well as complicated joints.

How it works?

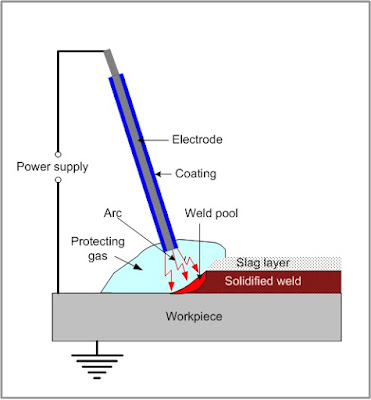

The typical shielded metal arc welding set up with an AC power source. The electrodes for the welding operation should be selected properly, depending on the requirements of the welding.

It can be done with either an AC or DC power source. The typical range of the current usage may vary from 50 to 500 A with voltages from 20 to 40 V.

Shielded metal arc welding uses a metallic consumable electrode of a proper composition for generating arc between itself and the workpiece. The molten electrode metal fills the weld gap and joins the workpiece.

The electrode is coated with a shielded flux of suitable composition. The flux melts together with the electrode metallic core, forming a gas and slag, shielded the arc and weld pool. The flux cleans the metal surface, supplies some alloying elements to the weld and then slag is removed after the solidification.

The main points to be considered in this welding process are the following :

Shielded metal arc welding is also called as manual metal arc welding. It is the most extensively used manual welding process, which is done with stick electrodes. Though in the USA, its use is decreasing in comparison to the other arc welding process. In India, it still is the most used arc welding process. This process is highly versatile and can be used extensively for both simple as well as complicated joints.

How it works?

The typical shielded metal arc welding set up with an AC power source. The electrodes for the welding operation should be selected properly, depending on the requirements of the welding.

It can be done with either an AC or DC power source. The typical range of the current usage may vary from 50 to 500 A with voltages from 20 to 40 V.

Shielded metal arc welding uses a metallic consumable electrode of a proper composition for generating arc between itself and the workpiece. The molten electrode metal fills the weld gap and joins the workpiece.

The electrode is coated with a shielded flux of suitable composition. The flux melts together with the electrode metallic core, forming a gas and slag, shielded the arc and weld pool. The flux cleans the metal surface, supplies some alloying elements to the weld and then slag is removed after the solidification.

The main points to be considered in this welding process are the following :

- Composition of the base metal, which determines the electrode composition.

- Tensile strength of the required joint.

- The thickness of the base metal. ( for thinner metal the current setting should be lower )

- Required metal deposition rate.

- Type of arc welding equipment used.

- Weld position - Flat, horizontal, vertical or overhead.

Advantages of shielded metal arc welding :

- A job of any thickness can be welded by shielded metal arc welding accept very small thickness below 3 mm may give rise to difficulties in welding because of their lack of rigidity.

- Simple, portable and inexpensive equipment.

- Suitable for outdoor applications.

- Wide variety of metals welding done by this process.

- Also, a wide variety of welding positions and electrodes are applicable.

Limitations of shielded metal arc welding :

- The slow speed of the welding process.

- The typical weld metal deposition rates may be in the range of 1 to 8 kg/h in the flat position.

- A lot of electrode material is wasted in the form of unused end, slag and gas.

- There are some chances of slag inclusion in the bead.

- Some precautions are needed to reduce moisture pick-up so that it does not interfere with the welding.

- Fumes make difficult the process control.