Construction and Types :

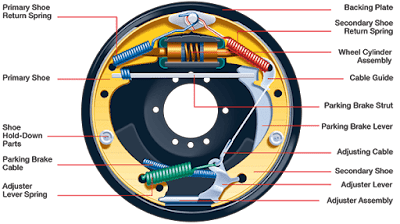

In this types of brakes, a brake drum is attached concentrically to the axle hub whereas on the axle casing is mounted a backplate. In case of the front axle, the brakes plate is bolted to the steering knuckle. The backplate is made of pressed steel sheet and is ribbed to increase rigidity and to provide support for the expander, anchor and the brake shoes are protects the drum and shoe assembly from dust and mud.

However, it absorbs the complete torque reaction of the shoe due to which reason it is sometimes also called a torque plate. Both brake shoes are anchored on the backplate. Friction linings are mounted on the brake shoes. Retractor springs are used to serve to keep the brake shoes away from the drum when the brakes are not applied. The brake shoes are anchored at one end whereas on the other hand force F is applied by means of some brake actuating mechanism. Which forces the brake shoe against the revolving drum, and hence applying the brakes. An adjuster is also provided to compensate for wear of friction lining with use.

The relative braking torque obtained at the shoes for the same force applied at the pedal varies depending upon whether the expander is fixed to the brake plate or floating If the anchor is fixed or floating and then the shoes are leading or trailing.

It is seen that a leading shoe tip is dragged along the drum even when there is no braking force, while the tip of the trailing shoe is thrown off the brake drum. Thus when the brakes are applied, the net force exerted on the leading shoe becomes more than the net force exerted on the trailing shoe and as such unequal braking effect is produced at the two shoes. With increased braking effect and consequently higher temperatures, the coefficient of friction gets reduced more with prolonged application in case of the leading shoe, due to which reason, leading shoe fades quicker than the trailing shoe.

Apart from the above disadvantage of the decreased braking effort, this type has got a definite advantage. It has better anti-fade properties than the two leading shoe type and thus provides more consistent braking.

Factors affecting braking effect :

In this types of brakes, a brake drum is attached concentrically to the axle hub whereas on the axle casing is mounted a backplate. In case of the front axle, the brakes plate is bolted to the steering knuckle. The backplate is made of pressed steel sheet and is ribbed to increase rigidity and to provide support for the expander, anchor and the brake shoes are protects the drum and shoe assembly from dust and mud.

However, it absorbs the complete torque reaction of the shoe due to which reason it is sometimes also called a torque plate. Both brake shoes are anchored on the backplate. Friction linings are mounted on the brake shoes. Retractor springs are used to serve to keep the brake shoes away from the drum when the brakes are not applied. The brake shoes are anchored at one end whereas on the other hand force F is applied by means of some brake actuating mechanism. Which forces the brake shoe against the revolving drum, and hence applying the brakes. An adjuster is also provided to compensate for wear of friction lining with use.

The relative braking torque obtained at the shoes for the same force applied at the pedal varies depending upon whether the expander is fixed to the brake plate or floating If the anchor is fixed or floating and then the shoes are leading or trailing.

- Fixed expander type :

It is seen that a leading shoe tip is dragged along the drum even when there is no braking force, while the tip of the trailing shoe is thrown off the brake drum. Thus when the brakes are applied, the net force exerted on the leading shoe becomes more than the net force exerted on the trailing shoe and as such unequal braking effect is produced at the two shoes. With increased braking effect and consequently higher temperatures, the coefficient of friction gets reduced more with prolonged application in case of the leading shoe, due to which reason, leading shoe fades quicker than the trailing shoe.

- Floating expander type :

- Floating anchor type :

- Two leading shoe type :

- Two trailing shoe type :

Apart from the above disadvantage of the decreased braking effort, this type has got a definite advantage. It has better anti-fade properties than the two leading shoe type and thus provides more consistent braking.

Factors affecting braking effect :

- The radius of the brake drum and the wheel

Where Retarding force produced on a brake drum

F = FB * Rb / Rw

- The area of the brake lining and the amount of pressure applied at the brake lining increases the braking effect directly.

- The higher coefficients of friction between braking surfaces and between tyre and road are also useful in increasing the braking effect, but two high coefficient may cause locking of wheels, which must be avoided.