What is involute?

The locus of the point on a straight line which rolls without slipping on the circumference of a circle is called the involute.

In other words, it is the path traced out by the end of a piece of the taut cord being unwound from the circumference of a circle. The circle on which the straight line rolls or from which the cord is unwound is known as the base circle.

Formation of involute tooth :

The locus of the point on a straight line which rolls without slipping on the circumference of a circle is called the involute.

In other words, it is the path traced out by the end of a piece of the taut cord being unwound from the circumference of a circle. The circle on which the straight line rolls or from which the cord is unwound is known as the base circle.

Formation of involute tooth :

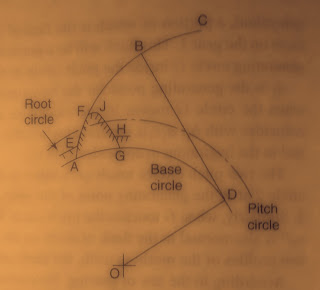

From the above figure, an involute generated by a line rolling over the circumference of a base circle with centre at O. At the start, the tracing point is at A. As, the line rolls on the circumference of the circle, the path ABC traced out by the point A is the involute.

D can be regarded as the instantaneous centre of rotation of B, the motion of B is perpendicular to BD. Since BD is tangent to the base circle, the normal to the involute is a tangent to the base circle.

A short length EF of the involute drawn from A can be utilized to make the profile of an involute tooth. The other side HJ of the tooth has been taken from the involute drawn from G in the reverse direction. The profile of an involute tooth is made up of a single curve, and teeth, usually, are termed as single curve teeth.

Notes :

Because of ease of standardization and manufacture, and low cost of production, the use of involute teeth has become universal by entirely superseding the cycloidal shape. Only one cutter or tool is necessary to manufacture a complete set of interchangeable gears. The cutter is in the form of a rack as all gears will gear with their corresponding rack. The cutters of this form can be made to a higher degree of accuracy as the teeth of an involute rack are straight.

Key points :

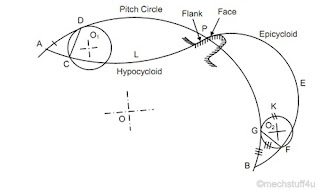

- Points of contact lie on the line of action which is the common tangent to the two base circles.

- The contact is made when the tip of a tooth of the driven wheel touches the flank of a tooth of the driving wheel and the contact is broken when the tip of the driving wheel touches the flank of the driven wheel.

- If the direction of angular movement of the wheels is reversed, the points of contact will lie on the other common tangent to the base circles.

- Initial contact occurs where the addendum circle of the driven wheel intersects the line of action.

- Final contact occurs at a point where the addendum circle of the driver intersects the line of action.

- For a pair of involute gears, the velocity ratio is inversely proportional to the pitch circle diameters as well as base circle diameters.