The Lenoir cycle is a thermodynamic cycle that can be invented by Jean Joseph Etienne Lenoir in 1860 is often used to model a pulse jet engine.

All type of process individually done in a heat engine in Lenior cycle.

The Lenoir cycle consists of four processes which are following below.

Process of Lenoir cycle :

All type of process individually done in a heat engine in Lenior cycle.

The Lenoir cycle consists of four processes which are following below.

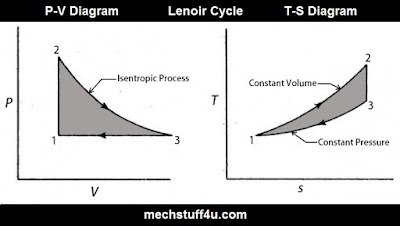

- A constant-volume gas expansion process. From the diagram shown below the ideal gas in the system absorbs some amount of heat from the heat source at a high temperature and then expands thus the work was done on surroundings.

- A reversible adiabatic gas expansion process. In this process, the system is thermally insulated. The gas expands continuously and does work on surrounding, which causes the system to cool to a lower temperature.

- A reversible isothermal gas compression process. In this process, work has done surrounding gas and cause a loss of heat.

- A reversible adiabatic gas compression process. In this process, surrounding continue to do work to a gas, which causes the temperature to rise back to high temperature attain in the first process.

|

| Lenoir cycle PV and TS Diagram |

The thermal efficiency of Lenoir cycle :

Thermodynamically, the efficiency of Lenoir cycle is given by

ŋLenoir = Work done by the system / Heat supplied to the system